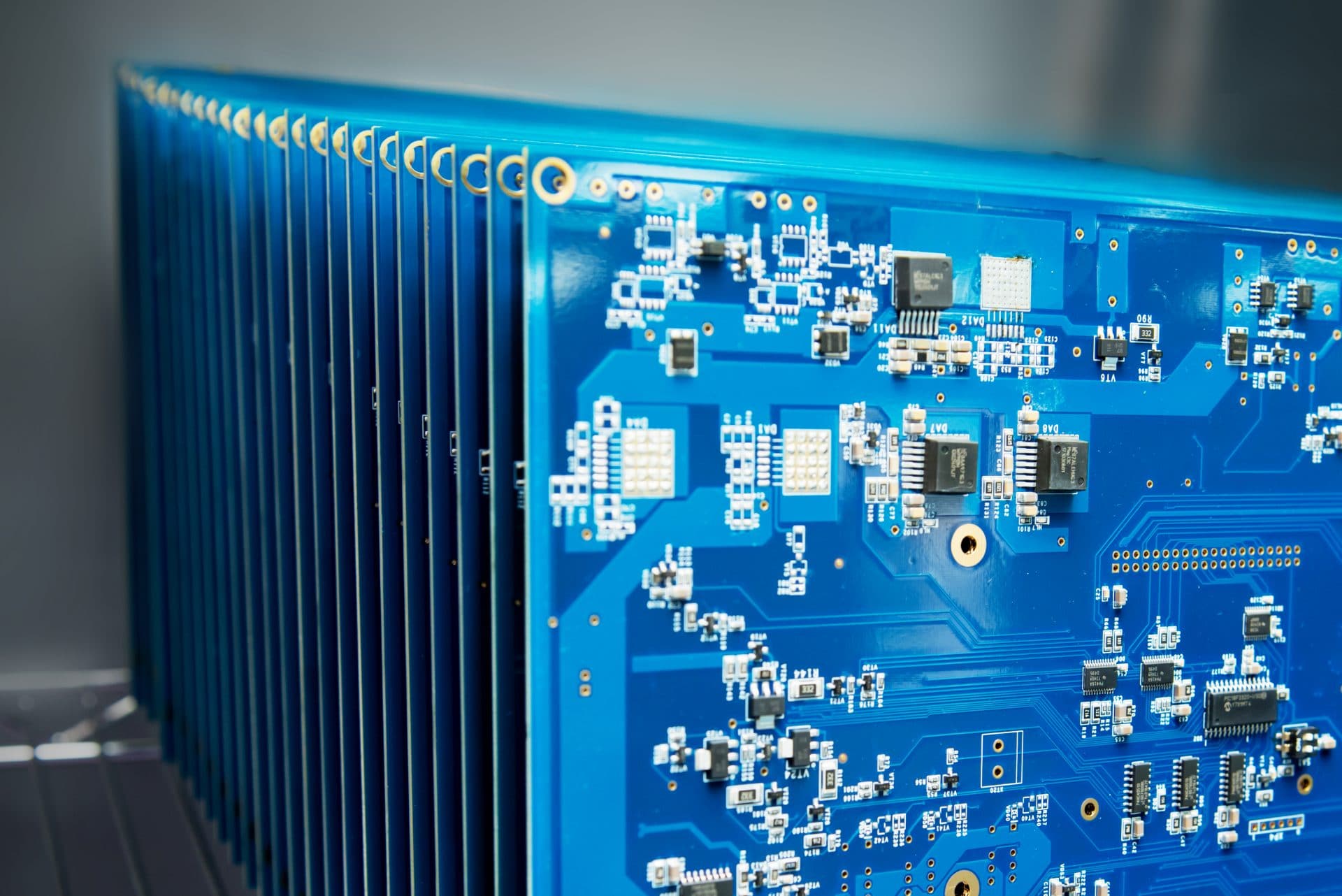

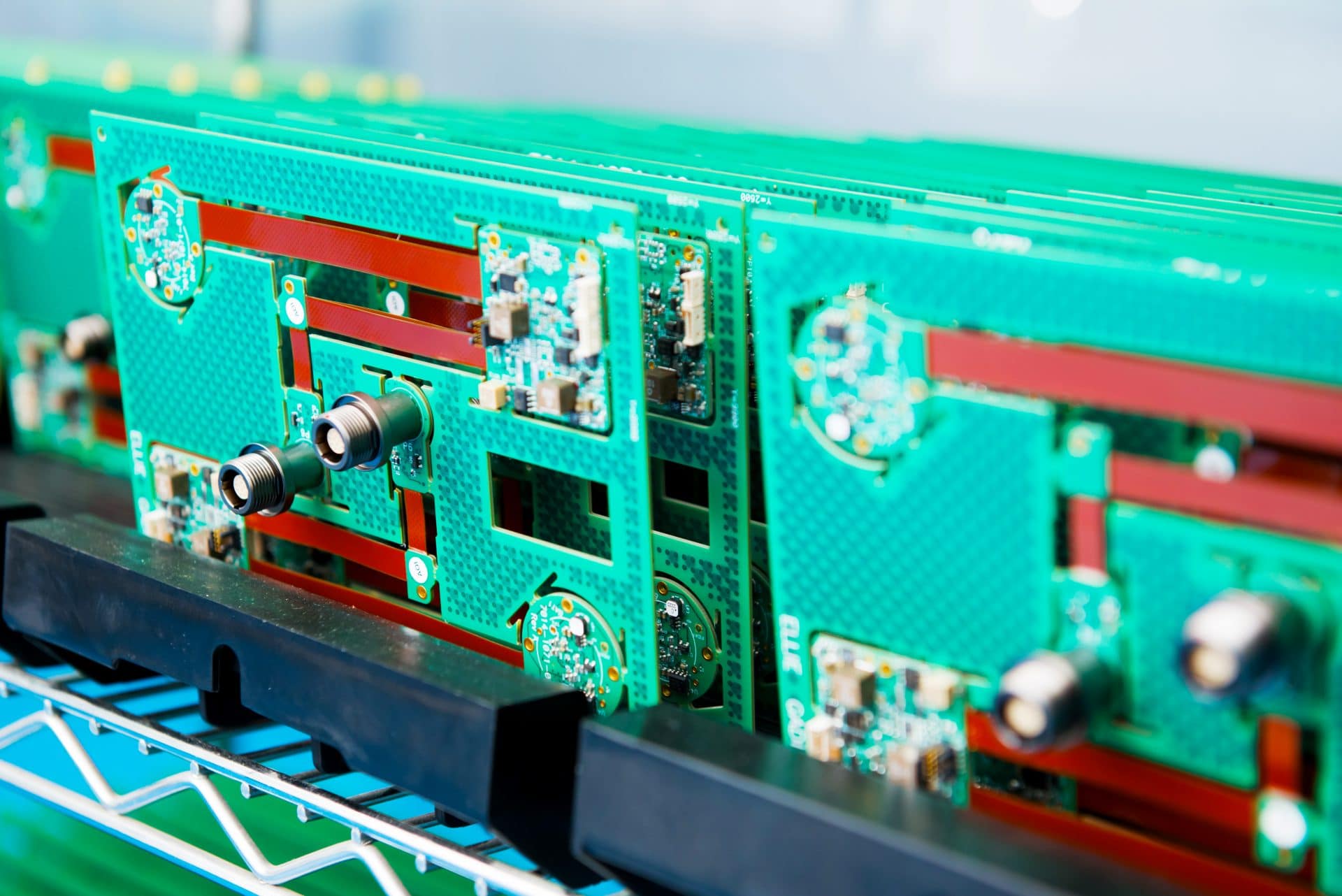

QC testing/Re-work service

All PCBs manufactured by Umeantech pass rigorous QC before delivery. However, what about PCBs not manufactured by approved PCB manufacturers worldwide that may not meet those same exacting standards? The complexity of boards and their configuration requires quick and efficient checking of layout/components (incorrect, polarity, offset, missing) and solder; that’s why Umeantech provides its QC testing/Re-work service.

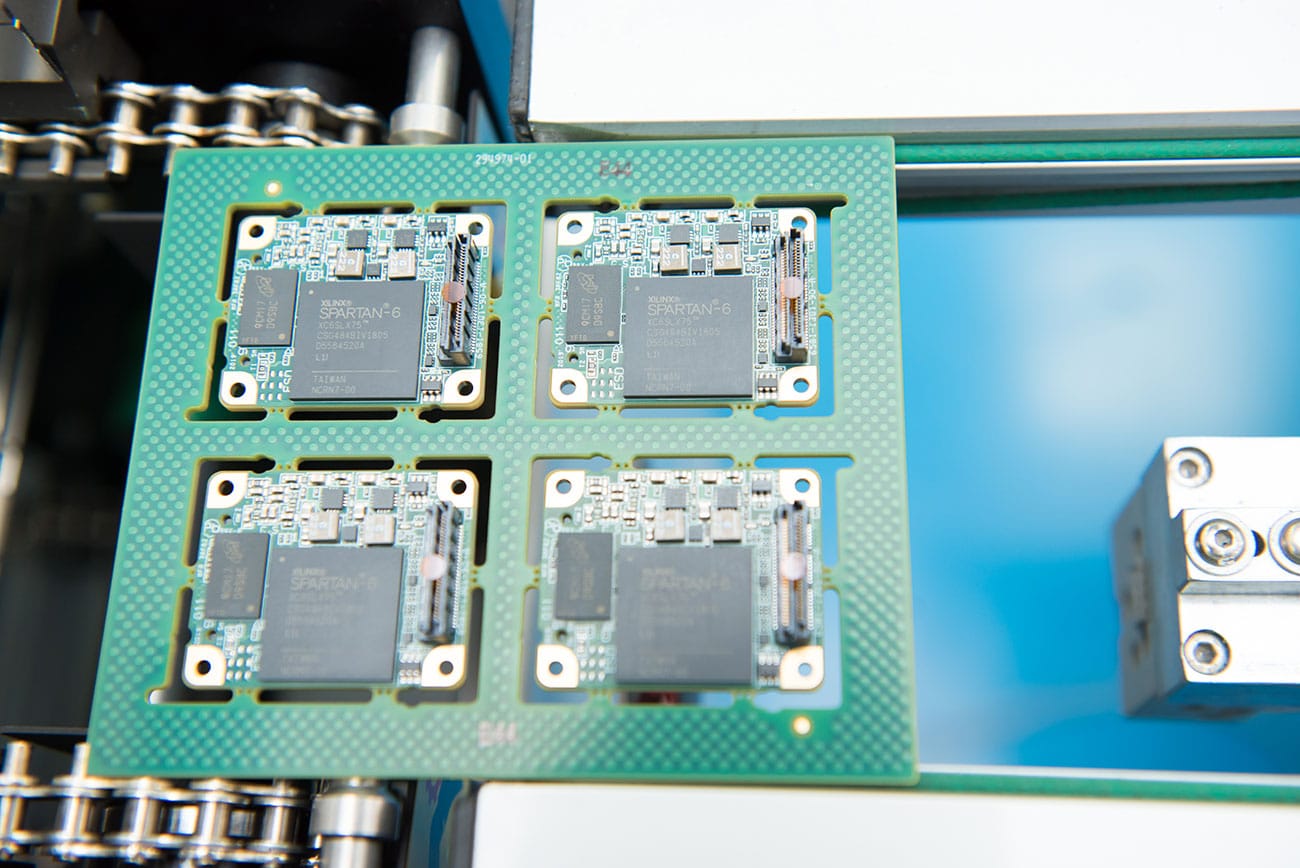

Aleader AOI

Utilizing cutting-edge AOI testing equipment, including an Aleader AOI machine to ensure the detection of all PCB defects, we will quickly get to the bottom of any faults in the PCB. The Aleader machine is capable of detecting a comprehensive range of defects and we are capable of checking components to a minimum size of 01005 inch.

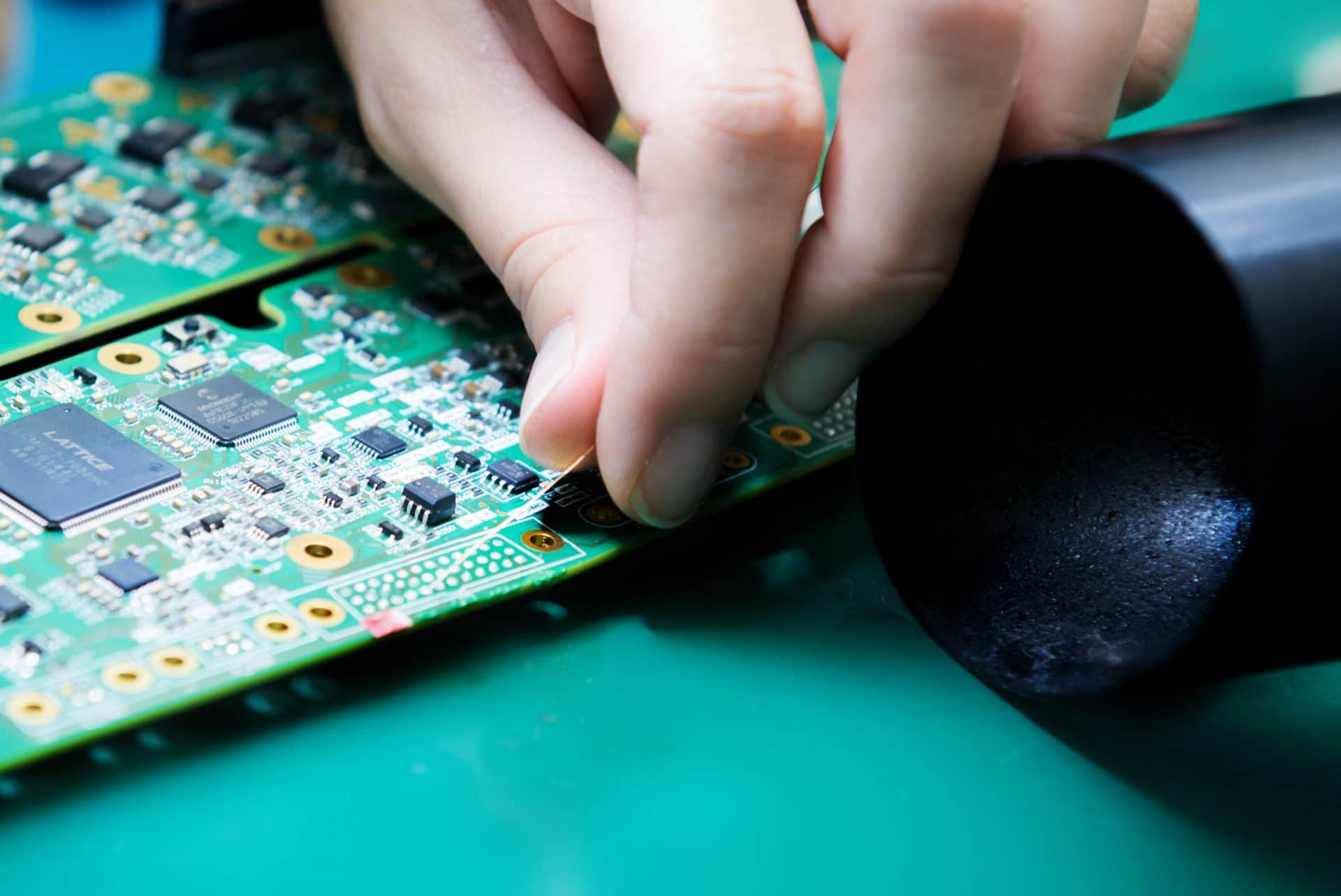

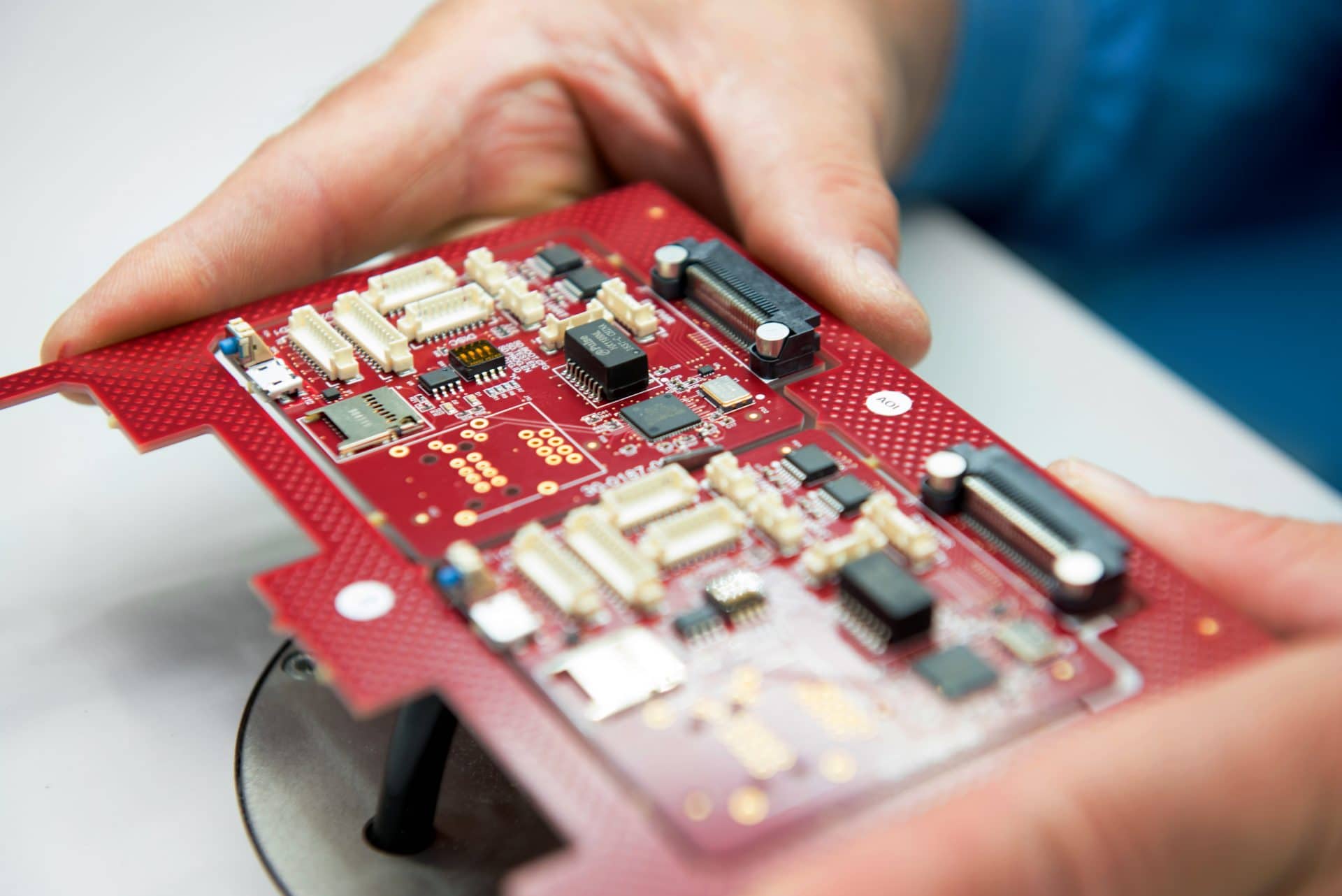

computerized parts inspection

We provide computerized parts inspection, solder print inspection as well as performance testing of PCBs to ensure they perform to specification.

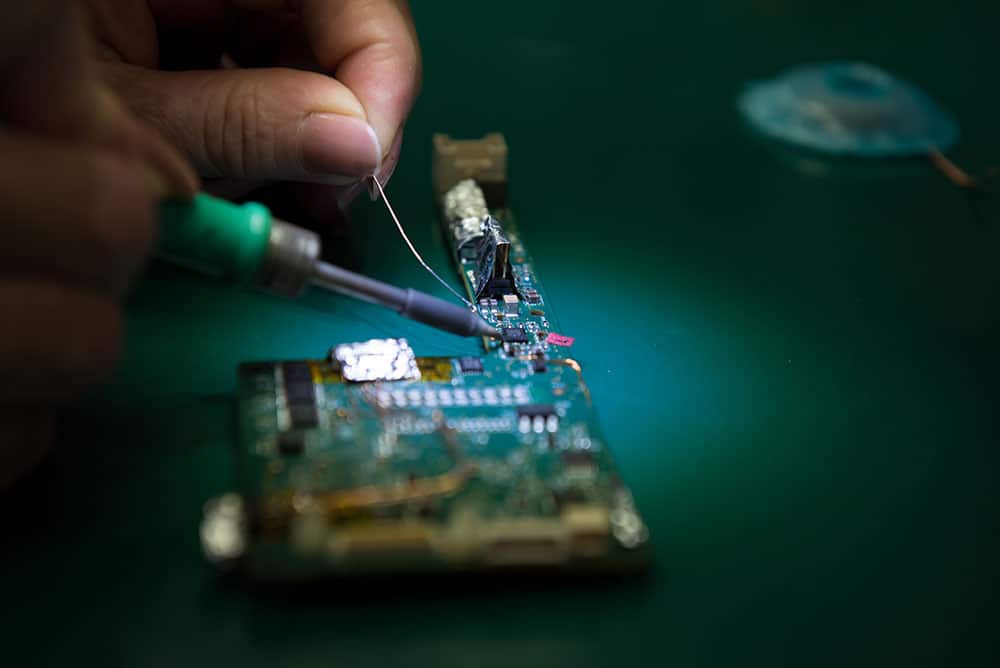

Failure analysis laboratory

In case you are experiencing any problems with your PCBs we are here to assist you.

We provide a vast failure analysis services as a comprehensive investigation failure report including X-RAY inspection , Laminography, etc.

With all this we insure to reach the root of the failure and provide an advise on what should be amended.