Umeantech MES

Umeantech MES (Manufacturing Execution System) – Aegis Factory Logix is an integrated suite of manufacturing execution system software modules and devices that adapt to and improve every aspect of your shop floor operations.

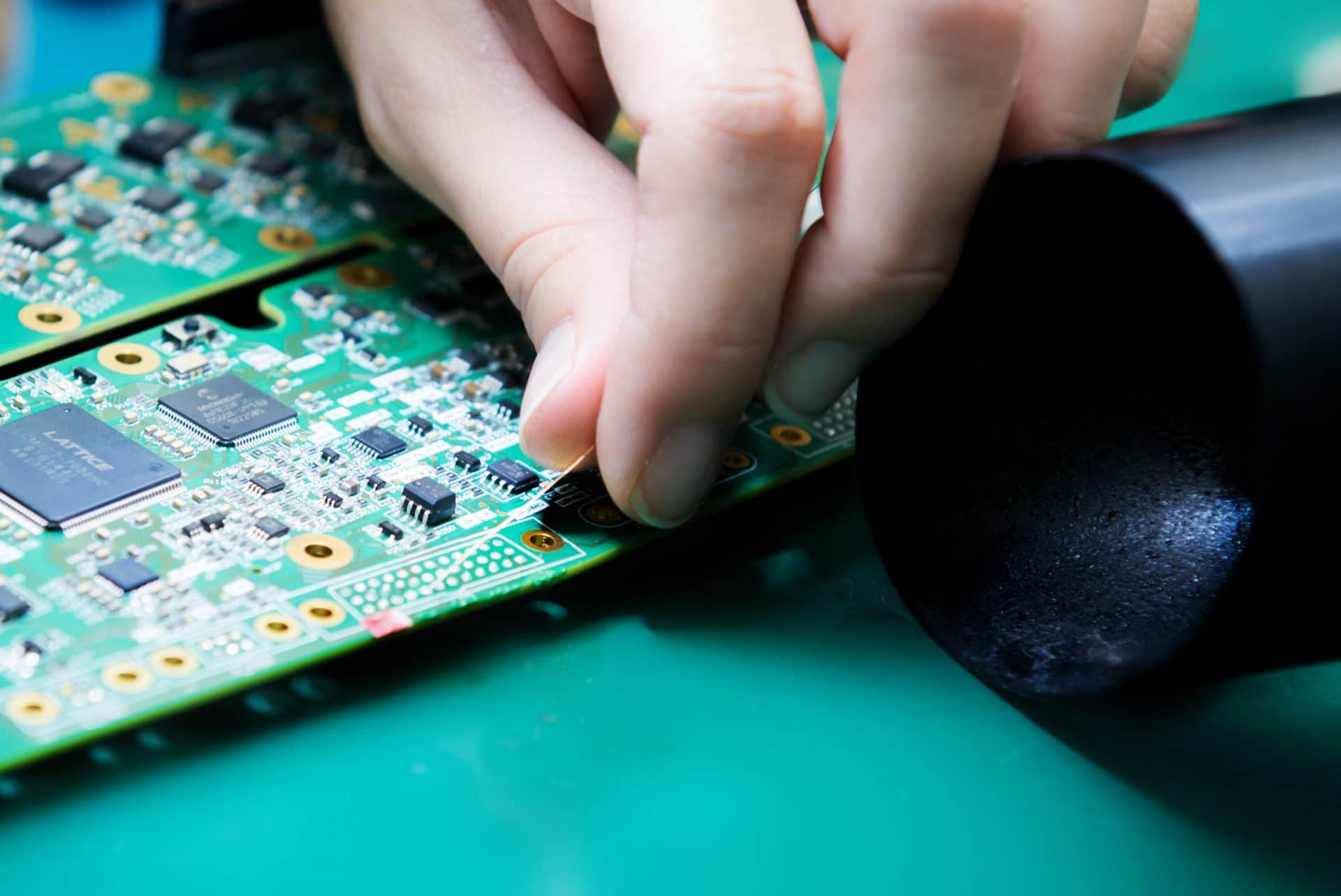

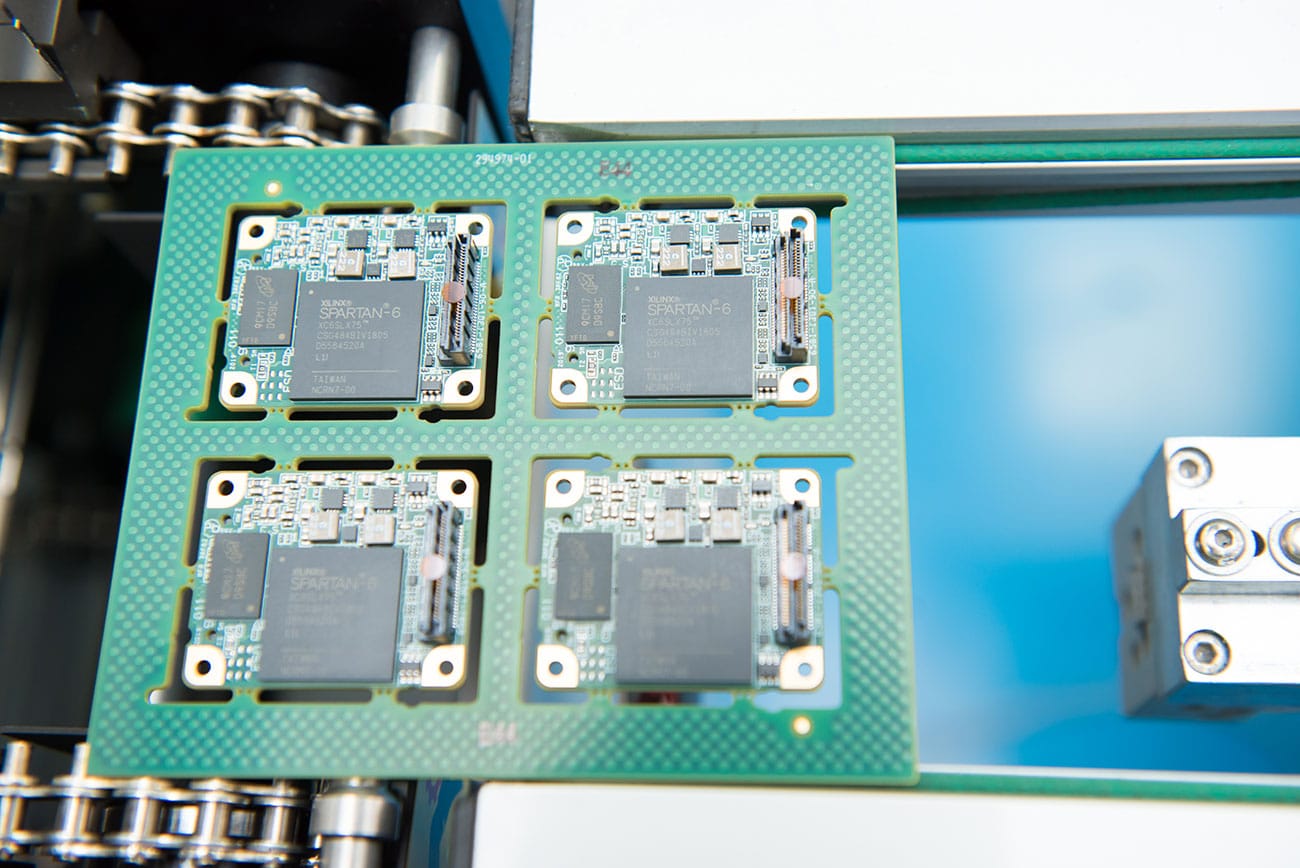

We support high mix projects with 01005,0201,0402, any kind of BGA/QFN including chip on chip.

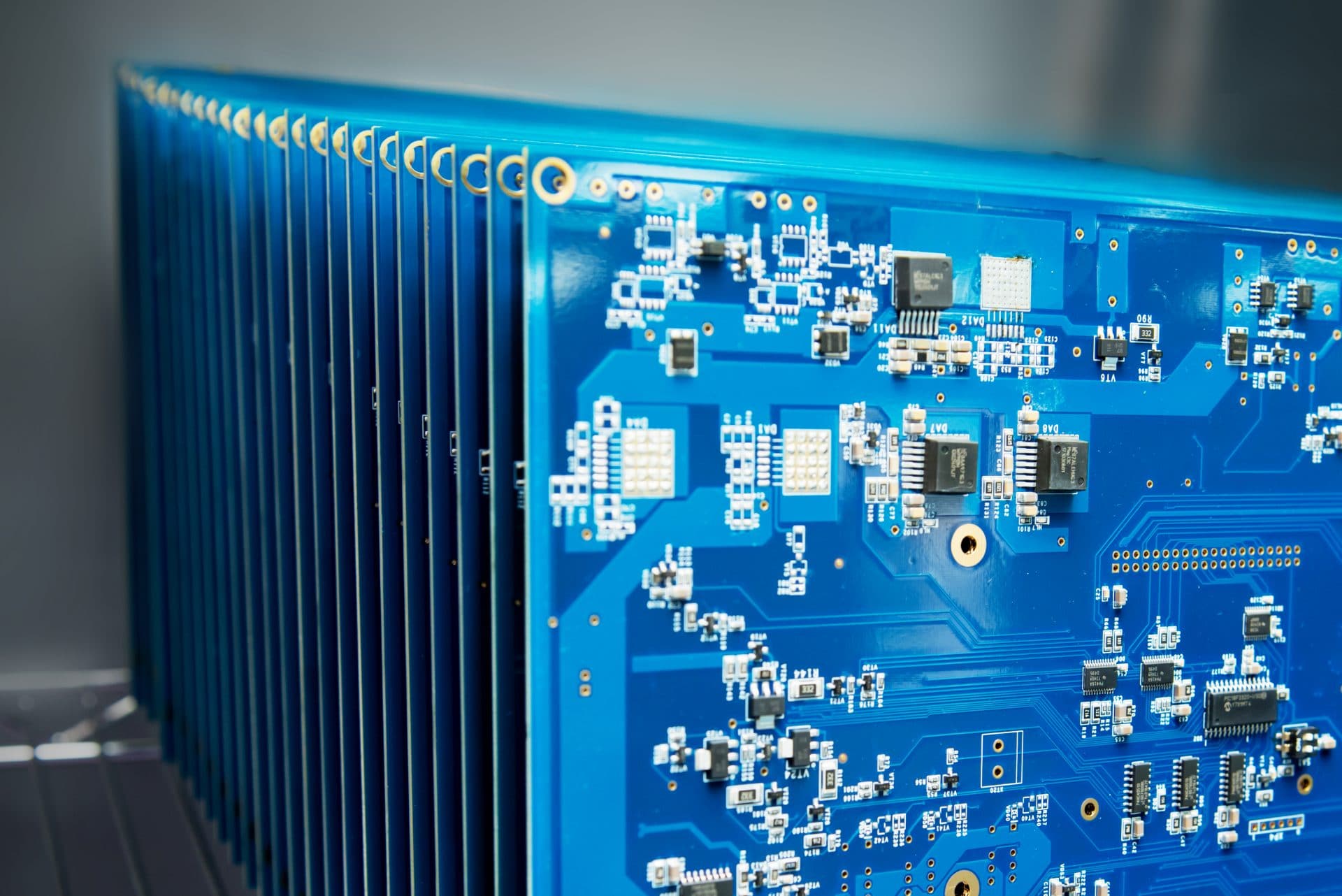

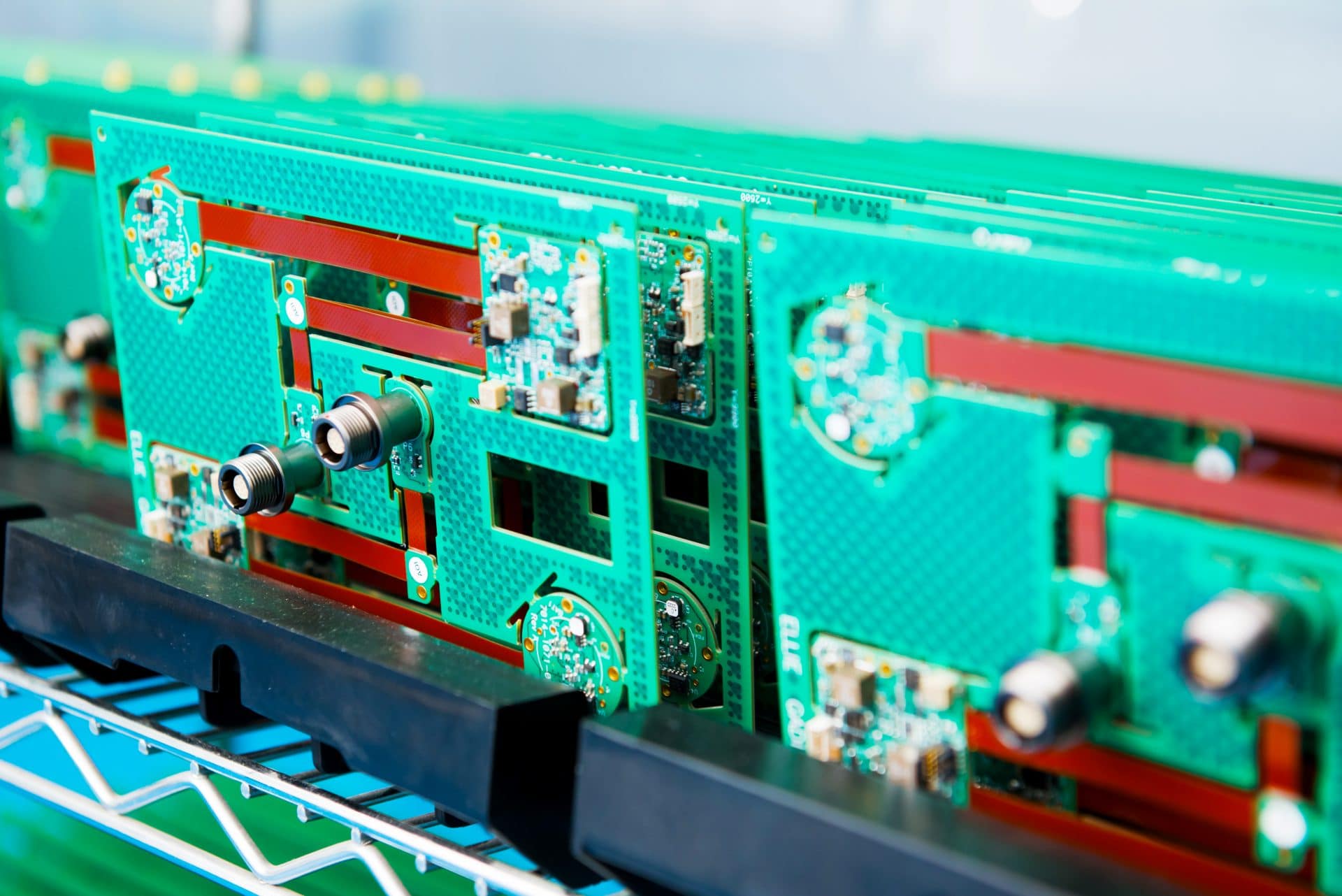

SMD (Surface Mounted Devices)

The solder paste is applied to the bare board by the ERSA/Yamaha screen printers. Our state-of-the-art Yamaha and PNP machines, automatically place the components on the board where the Heller Reflow ovens, which have 8 heating and 2 cooling zones, do the soldering. The Aleader AOI automatically performs an optical inspection and the board is also inspected visually.

A Nikon 3D X-RAY Inspection System is used to inspect specific soldered joints and voids.

SMD - Inspection

Inspection can be performed in four ways:

- Visual Inspection – Measurement Inspection

- Automatic Optical Inspection (AOI)

- FAI – First Article Inspection

- X-RAY for BGAs, QFNs, etc.

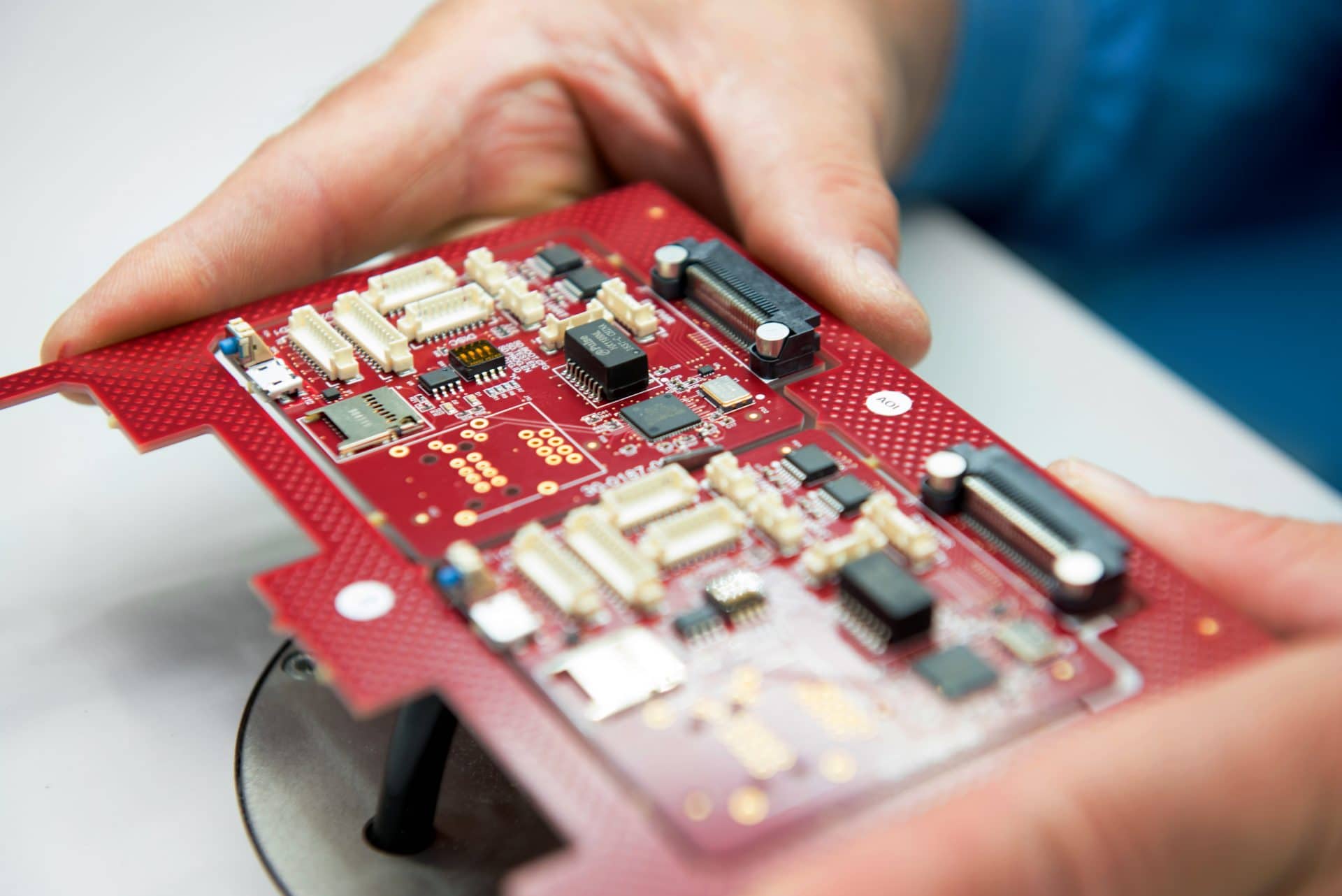

Overview of Activities -following completion of the SMD Production Phase:

Rework / Reballing for any BGA design

Component bending / Component cutting

Mounting heatsinks, wiring, etc.

Mechanical assembles

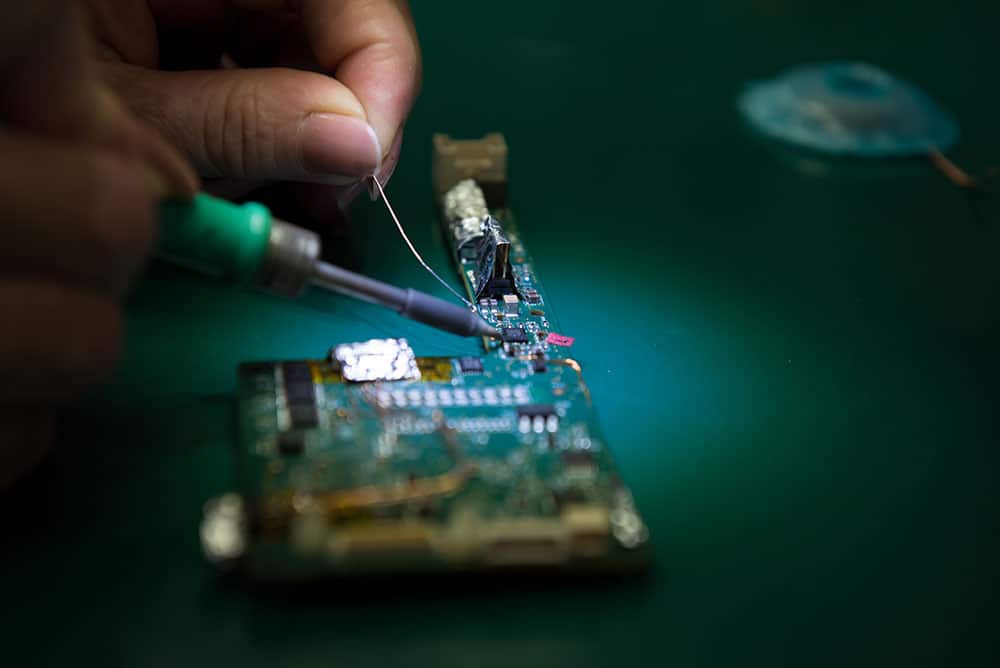

TH soldering: Manual, Selective

Glue / Coating

Burning software

Functional testing

Adding serial numbers / Packing

Laminography